Safe flutter tests with enDAQ’s wireless accelerometers

Reading time: 3 minutes

Client challenge: Perform safe, objective, and cost-effective flutter testing to clear a complex flight envelope and achieve a fully certified commercial aircraft

When developing a new aircraft, flutter testing is at the forefront of every aerodynamicist’s mind. Flutter – a self-excited vibration caused by aerodynamic, inertial, and elastic forces that affect the motion of the wing of an aircraft – can cause structural damage leading to catastrophic crashes. Flutter needs to be designed for and tested for – not only on the ground, but also in flight.

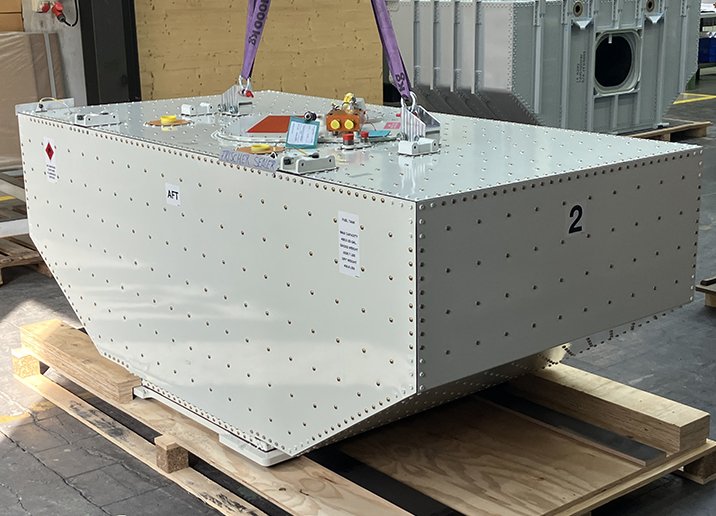

For smaller aviation startup companies like Stratos Aircraft – a jet manufacturer from Redmond, Oregon, who are developing an Experimental-designated single-engine, transonic jet – qualifying a fully-cleared commercial aircraft via standard flutter testing can be prohibitively expensive. To compensate for smaller budgets, aircraft start-ups seeking clearance of an Experimental aircraft often rely on pilot perception of stick and rudder pedal raps to develop flutter clearance of flight envelopes.

Stratos Aircraft deemed this approach to flutter testing far too risky and subjective. If they wanted to achieve a fully cleared commercial certified aircraft through the Experimental route, they would need a novel and objective approach to test flutter to clear a complex transonic flight envelope.

Our solution: Measure excitation through distributed wireless sensors on a Proof of Concept aircraft.

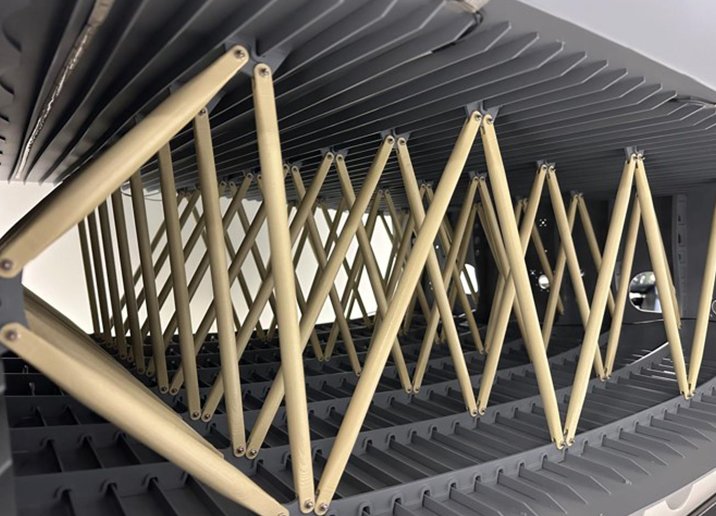

In the case of Stratos’s particular application, enDAQ provided customized wireless sensors based on the W8-E25D40. The customization allowed for the devices to be affixed to the aircraft without altering the mass or structure of the aircraft. Designed to survive harsh environments, Stratos could trust that the data collected from testing both on the ground and inflight would be reliable, accurate, and actionable.

Stratos mounted enDAQ’s portable, self-contained sensors at discrete locations on the airframe of their Proof of Concept (PoC) aircraft. This disbursement allowed for monitoring and evaluation of the wing’s main bending and torsional modes which are critical behaviors of the PoC aircraft. With the sensors’ GPS and wireless capabilities, the time stamped data allowed for exact synchronization of the devices. This was crucial in clearing the flight envelope as it proved sufficient in differentiating between symmetric and antisymmetric motions.

To perform their testing, Stratos needed to excite the PoC aircraft. Pilots conducted stick and pedal raps with a dead blow hammer, they stomped on the pedals, and used airspeed brakes.

The test data provided by enDAQ’s distributed wireless sensors revealed that stick and pedal raps excited higher frequency modes than expected (up to 15 Hz). The data also demonstrated that the airspeed breaks were extremely effective at getting a broadband frequency excitation of the entire airframe (exiting modes between 15 - 40 Hz). E/AB manufacturers like Stratos can get an excellent response using these excitation modes.

Results: Successful flight envelope clearance of Stratos’s PoC aircraft

The data collected by enDAQ’s distributed sensors helped Stratos establish that there were no trends indicative of flutter within their PoC aircraft testing data leading to successful flight envelope clearance of their PoC aircraft.

Testing and data analysis demonstrated that frequency response of stick and pedal raps (up to 15 Hz) may be more valuable in flutter testing than previously thought.

Additionally, testing revealed that airbrake deployment was also effective at exciting modes between 15 Hz and 40 Hz. enDAQ’s self-contained sensors enabled this novel approach to testing. Not only was this solution a more affordable testing option that would yield accurate, high quality data, its installation required minimal adaptations and did not interfere with the structure of the aircraft.

Stratos’s successful approach to clearing their PoC flight envelope indicates that using enDAQ sensors to measure and analyze the response from stick and pedal raps and other broadband structural excitations may be an alternate means of flutter clearance testing for E/AB aircraft manufacturers