Hutchinson's innovative composite rods help reduce weight of Airbus A350 freighter

Reading time: 3 minutes

Client challenge: Improve the weight saving of primary structural rods in freighter aircraft

Airbus came to Hutchinson looking for extreme weight optimization for its composite solutions, namely the structural rods used in the new version of its A350 freighter aircraft. For the freighter variant of the A350, the issue of weight was omnipresent and critical in order to achieve the program's objectives in terms of capacity and performance.

Existing structural rods process are based on filament winding, Resin Transfer or extrusion.

Rods which are designed for these processes do not offer an optimum strength-to-weight ratio. To support the much higher loads carried by a freighter, these rods would have been significantly heavier and more costly.

Could Hutchinson’s materials experts create a new type of rod that would offer better strength-to-weight?

Our solution: Create structural rods optimized for the application

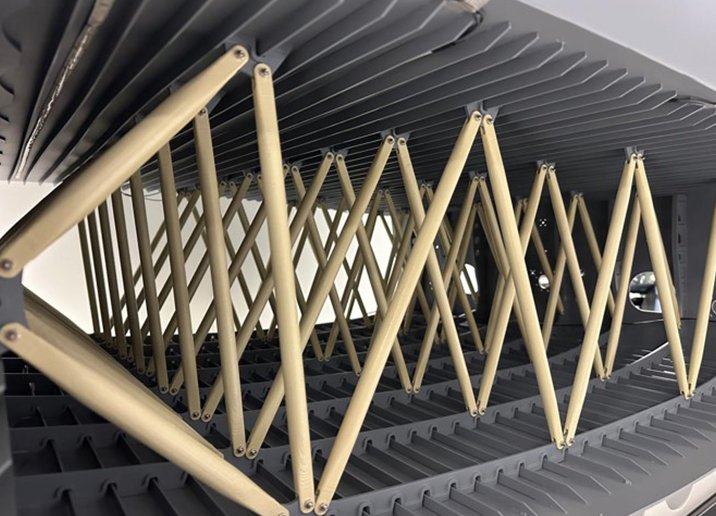

To circumvent the limitations of the traditional processes, Hutchinson opted for a molding process optimizing the use of carbon fiber.

Laying strips of carbon fiber in a specifically optimized pattern into a tool, we were able to play with the fiber's performance and create rods where all carbon fibers were oriented and optimized according to the stress flow. This greatly improved the mechanical performance of the material while keeping its thickness and weight to a minimum.

This way of working had not been used before to create structural rods of this type for the aerospace market. It was developed and tested at Hutchinson’s research center in Montargis, France, in close partnership with Airbus.

Customer benefits: Stronger, Lighter rods for larger, heavier loads

After an extensive test campaign on dedicated test lab equipments, the new rods proved capable of withstanding all functional specifications requested by the customer.

By integrating Hutchinson's rod design, Airbus A350 freighters can carry heavier loads, improving efficiency for Airbus’s customers. As they are lighter than the traditional solution, this Hutchinson product also improves fuel economy, helping to reduce costs and increase the sustainability of each flight.

Our design integrated seamlessly with Airbus’s existing center wing box, so no additional modifications had to be made to the A350F before installation. The customer’s costs were also reduced compared to the previous solution.

As Hutchinson has internal expertise and vertically integrated testing capabilities, we were able to offer a complete, end-to-end solution, including design, testing, production, qualification, and delivery of finished shipsets.

Properties

- Tensile & Compressive Load Capacity: From 30 tons

- Damage and Fatigue Resistance

- 20% weight saving compare to traditional solutions

- Materials: epoxy resin reinforced by carbon fiber

Results: Two shipsets delivered, four more due in 2025

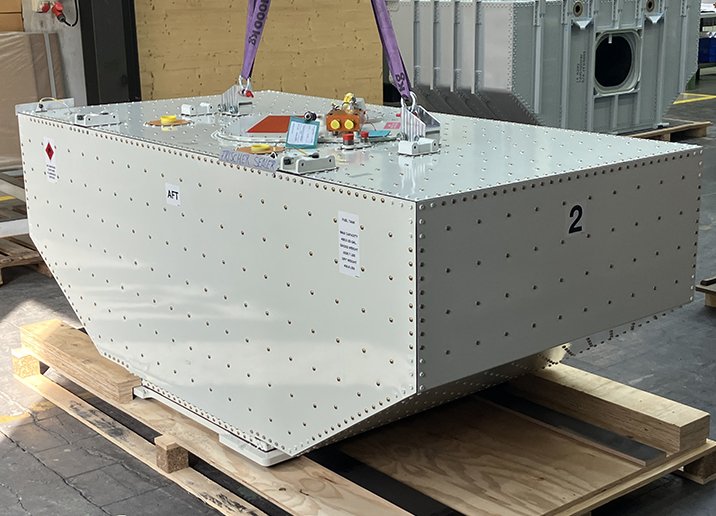

Hutchinson delivered the first shipset to Airbus in June 2024 and the second in January 2025. Four more complete shipsets, each comprising 72 structural rods, are scheduled for delivery this year.

Our new approach allows Airbus’s freighters to safely withstand larger loads without compromising performance or adding additional weight. With our integrated solution, including research, testing, manufacture, and qualification, Airbus enjoys a simplified supply chain and reduced total costs.

Innovating an original approach to a customer challenge is what we do every day at Hutchinson. If your industry is facing an issue that you’ve been unable to solve, bring it to our multi-material experts, and together we’ll work on a new solution that could unlock value for your business.