- Rotary and Shaft seals

- Rotary and Shaft seals

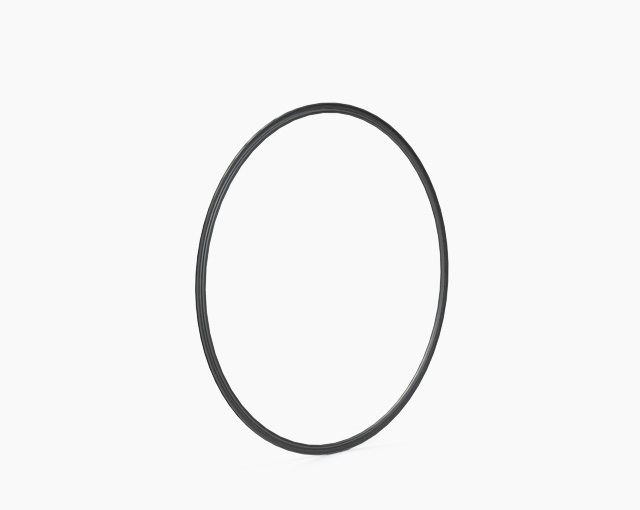

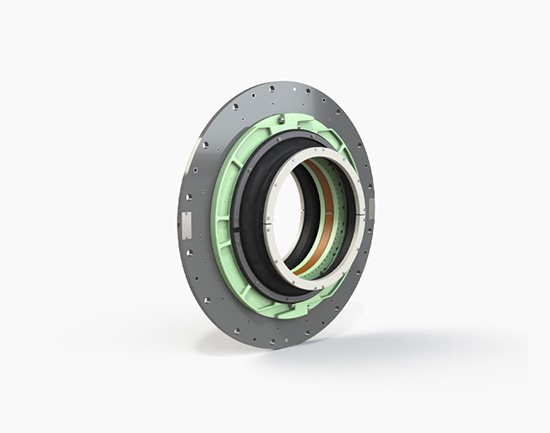

Bearing seals

Seals that protect bearings from pollution and ensure the smooth operation of aerospace and defense systems. Made from high-performance materials, they withstand external aggressions and achieve an optimal balance between sealing efficiency and torque, to help reduce energy consumption and CO2 emissions. Bearing seals are commonly used in engines, swashplates and tail rotors, providing reliable protection and extending the life of critical components.

Low friction to reduce energy consumption and CO2 emissions

Robustness: Durability and reliability of bearings

Recognized solutions: Over 50 years of certified sealing solutions

Increased service life

Key features

Applications

- Engines

- Swashplates

- Tail rotors

- Intermediary bearings

Characteristics

- Operation in harsh environments: mud, sand, salt…

- Wide temperature range: -55°C to +200°C

- Low friction forces

- Compatible with fluids used in aerospace applications

- Design options: cassette seals, multi-lip seals, solutions with magnetic tracks

- All sizes up to 500 mm

Our strengths

- Expert in the development and manufacturing of elastomers

- Fully integrated manufacturing process

- Build-to-spec or build-to-print

- EN9100-certified factory

- Traceability and certificates of conformity

Commercial Aviation

Business and General aviation

Rotary Wing

Aerospace defense

Ground mobility

Navy

Advanced air mobility

Space